Production of Biodegradable Packaging Material From Non-Animal-Based Ingredients Such As Corn Starch and Grape Seed Tannins

Food Science| Siddharth Ravi

The numerous environmental and health impacts of plastic packaging mean it is essential to find alternatives. Plastics have complex chemical structures that seldom occur in nature, implying that microorganisms cannot degrade them. In contrast, biopolymers are substances that mimic the properties of plastics but are completely biodegradable. Corn starch is the most viable among starch varieties, and was selected for this research. Biopolymers require strengthening to be effective as packaging materials, and plasticisers such as glycerol are commonly used for this purpose. Grape seed tannins were incorporated as antioxidants for the films to scavenge free radicals, preventing food spoilage.

1. Introduction

The last decade has seen a huge rise in demand for alternative packaging materials to replace plastic. The rising concern is owing to the damage caused by plastic to both health and the environment. But what makes plastics so threatening? Plastics cannot be degraded naturally due to their chemical composition, which is rare and alien to microorganisms involved in biodegradation. The accumulation of undegraded plastics over centuries also leads to toxin release. This makes them one of the leading threats to health and the environment, triggering the search for alternatives.

The primary focus of most current research is to develop packaging materials that are biodegradable. How wonderful would it be if plastics themselves were made biodegradable? So far, research has unearthed a few polymers that can be biodegraded. Polymers, in brief, are the structural and functional units of any plastic material. Therefore, these are biodegradable, and a large proportion of the problem is solved [1]. These biodegradable polymers are called "biopolymers" [2]. At the moment, gelatine is the most popular biopolymer, and has been used extensively [3]. However, gelatine is extracted from animal bones and has recently attracted criticism for causing health issues. Moreover, people who don't consume animal products are often uncomfortable buying products packaged in animal-based material.

The lookout for a plant-based alternative has been on the rise over the last few years. Data reveals that starch could be the ideal alternative to gelatine. Starch has been extracted from several sources, but corn remains the most economical and dependable source. Corn starch is composed of amylose and amylopectin, which have linear and branched structures linked by alpha (1,4') linkages and alpha (1,6') linkages, respectively. Hydrogen bonding links the hydroxyl groups, making this biopolymer strong and flexible. In addition, any product needs performance bolsters, and in the biopolymer industry, plasticisers are those substances. They mainly assist in hydrogen bonding. Glycerol is a top plasticiser, and with its desired water retention properties it is a go-to material [4]. However, we should not focus on strength and durability alone. "Smart packaging" is now the priority, with a focus on food preservation.

The primary objective of preservation is to protect food material against unwanted chemical reactions. The main reaction responsible for the spoilage of food is oxidation, where free radicals present in the atmosphere interact with the food material and oxidise it, rendering it spoiled.

To prevent this from happening, antioxidants are incorporated into the packaging material. One such antioxidant that also enhances mechanical character is grape seed tannins. These tannins scavenge free radicals and neutralise them, preventing oxidation. This occurs due to the phenolic compounds in the tannins [1].

Research concluded that the incorporation of grape seed tannins in gelatine films elevated mechanical properties while also acting as highly efficient antioxidants [2]. Grape seed is one of the most common antioxidants in the food industry, thus substantiating its position [5]. This research aims to combine corn starch, glycerol, and grape seed tannins in a well-optimised process to yield highly durable, strong, and smart biofilms for foodstuff packaging.

2. Materials

Organic corn starch (purchased from a supermarket at Henderson, Auckland), grape seed tannins (supplied by Tarac Australia Ltd, Australia), glycerol (Sigma Aldrich), milli-Q water, sodium bromide (Sigma Aldrich), ABTS 2,2-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt) (Sigma Aldrich), and potassium persulfate (Sigma Aldrich).

3. Methods

3.1. Biofilm preparation

A 5% corn starch solution was prepared by mixing 5g of corn starch in 100 ml of Milli-Q water, and 2.6 mL of glycerol was added to the corn starch mixture. Tannins were added at concentrations of 0.8%, 2.5%, and 4% of the corn starch mass. The mixture was continuously stirred using a magnetic stirrer for 10 minutes, followed by shaking in a water bath at 85°C for 30 minutes. After the water bath treatment, the solution was filtered through a sieve, and the films were cast in 25 mL moulds. The films were dried for 24 hours at 40°C in a hot air oven. Once dried, the films were placed in a desiccator containing saturated sodium bromide solution for 48 hours, maintaining humidity levels at 56% (Figure 1). After the incubation, the films were analysed for mechanical and antioxidant propertises.

Figure 1: Procedure flowchart

3.2. Mechanical properties

Several mechanical properties of the films such as tensile strength, elongation at break, and Young's modulus were recorded using an Instron 5943 mechanical testing system.

3.3. Water contact angle

Water contact angle may be described as the angle formed by a droplet of water with the surface of a material. When this angle is a right angle or greater, it denotes a hydrophobic character of the material. Lower values indicate a hydrophilic nature. Hydrophobicity is indicative of water resistance, which is important for a packaging material to prevent water-induced spoilage of food. The films were analysed using an optical contact measuring instrument (CAM 100 software, KSC instruments Ltd., Finland).

3.4. Solubility in water

Solubility in water is another crucial factor to note while designing packaging material. If the material is soluble in water, it nullifies the purpose of the packaging material, as disintegration would expose the food, leading to spoilage. The films were immersed in water for 60 minutes and then dried at 40°C for 24 hours.

3.5. Antioxidant property

Antioxidant activity may be described as the ability of a material to prevent oxidation of the packaged food. Free radicals are chiefly responsible for the oxidation of food, leading to spoilage. Antioxidants are substances that neutralise the free radicals by scavenging them, hence preventing spoilage. Phenolic compounds are majorly responsible for this antioxidant character and they are abundant in tannins. To determine the antioxidant effect of the films, the 2,2-azinobis (3-ethylbenzothiazoline-6-sulfonic acid) diammonium salt (ABTS) assay was carried out.

ABTS interacts with potassium persulfate to form ABTS radicals, changing the originally light green solution into dark blue. When films are immersed into this solution, it transitions from dark blue to yellow to colourless, due to the presence of phenolic compounds in tannins (Figure 2).

3.6. Attenuated Total Reflection - Fourier Transform Infrared (ATR-FTIR) Spectroscopy

ATR-FTIR spectroscopy was employed to detect the functional groups present in the biofilms to confirm the presence of phenolic compounds. Each type of functional group in a substance responds to a different wavelength of infrared radiation with a unique vibration pattern that can be detected.

4. Results

Figure 2: Colour change observed upon reaction

4.1. Biofilms

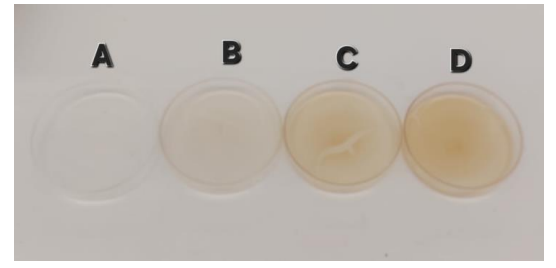

The addition of tannins aimed to enhance the mechanical and antioxidant activity of the films, improving their efficacy as foodstuff packaging material. Different concentrations of tannins were used to determine the optimal level in terms of these properties. As the concentration increased, the depth of colour of the films also increased, and this change was visible to the naked eye (Figure 3).

4.2. Mechanical properties

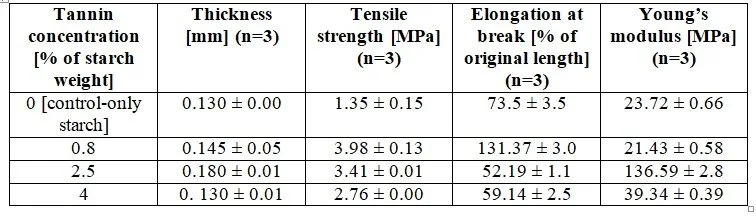

When compared to films with no tannins (control films), the films incorporated with tannins had improved mechanical character (Table 1). The control films we used exhibited similar mechanical character to date palm pits used in previous research by Alqahtani et al. [1]. In contrast, the tannin-infused films showed mechanical improvements, with the 0.8% tannin films demonstrating the best mechanical properties (Table 1).

Young's modulus describes the stiffness of the material. A certain level of stiffness is expected of a packaging material, and this experiment shows an appreciable improvement of Young’s modulus. Tensile strength is a measure of the maximum amount of stress a material can withstand, and an immediate improvement was observed upon adding tannins. Furthermore, the elongation at break is the maximum extent to which a material can be stretched before snapping and exposing the product packed within. Since some flexibility is desired, we expect an optimal level of extension to occur at some point, and the results suggest a close-to-optimal stretching occurred in the 0.8% tannin films.

As observed by Etxabide et al. [3], the 1% tannin concentration was optimal in terms of mechanical properties as the 0.8% concentration proved to be best.

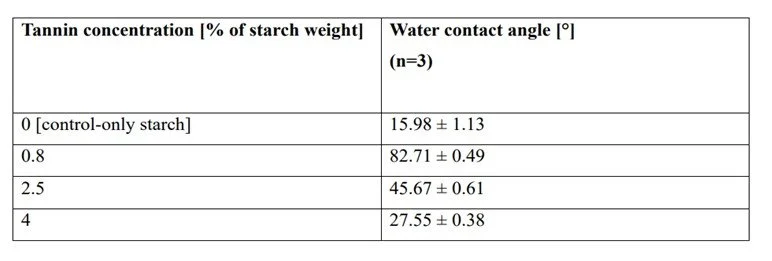

4.3. Water contact angle

The results indicated an increase in water contact angle upon the initial addition of tannins. However, in biofilms with tannin concentrations exceeding 0.8%, water contact angle decreased (Table 2).

The low water contact angle of the control films could be attributed to the presence of a large number of hydroxyl groups in starch molecules. The addition of tannins increased hydrophobicity by bonding to polar groups, thereby reducing the hydrophilic character of the films and raising the water contact angle. However, at higher concentrations, tannins introduced more unbound hydroxyl groups, which also contributed to the hydrophilic nature of the surface. This increase in unbound hydroxyl groups reduced the contact angle compared to films with lower tannin concentrations, but it still remained higher than in control films.

Glycerol concentration has been observed to be inversely proportional to hydrophobicity in previous research by Basiak et al. [6]. However, since the glycerol amount was kept constant in this study, the focus is on tannins. According to Etxabide et al. [3], tannin concentration of 1% was optimal, but in this case, 0.8% proved to be most effective, resulting in an 80-degree contact angle and demonstrating clear hydrophobic character.

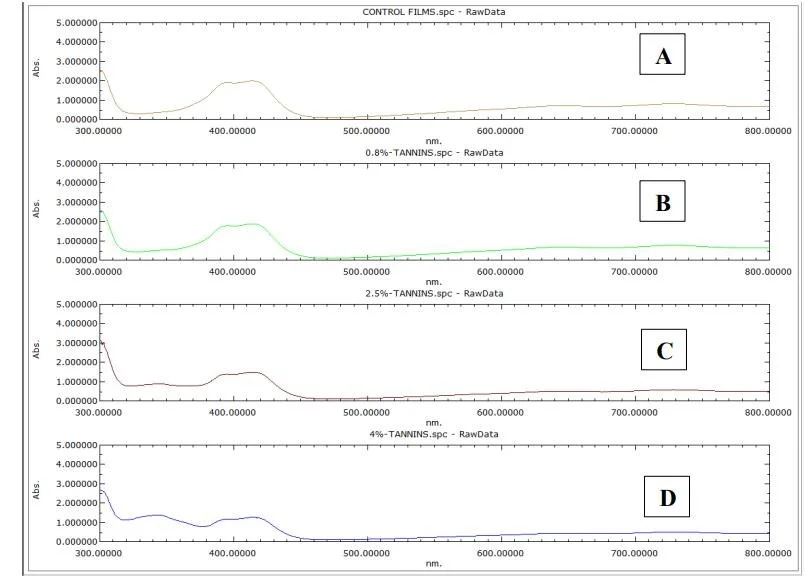

4.6. Attenuated Total Reflection - Fourier Transform Infrared (ATR-FTIR) Spectroscopy

Upon performing this analysis, various functional groups were detected at different wavelengths (Figure 7). The OH group, indicative of phenolic presence, was detected at 3300 cm-1.

Research by Ma et al. [8] is proof to the correctness of the experiment, and the observed OH group indicates antioxidant activity. NH observed at 3200 cm-1 is further evidence for antioxidant character. The observation of an amide group at 1650 cm-1 illustrates the resilient and durable nature of the film. Ma et al. [8] again conclude the same. Chhatariya et al. [9] and Etxabide et al. [3] produced similar outcomes, substantiating this study.

Figure 5: Computer generated UV-Spectra of different concentrations of biofilms

Figure 6: Comparative study of the spectrum for each film

Figure 3: Biofilms produced presented in the increasing order of colour depth and tannin concentration [Left to Right (A TO D)].

Table 1: Mechanical properties of biofilms casted.

Table 2: Water contact angle of biofilms.

Figure 4: Water contact angle of 0.8% tannin films

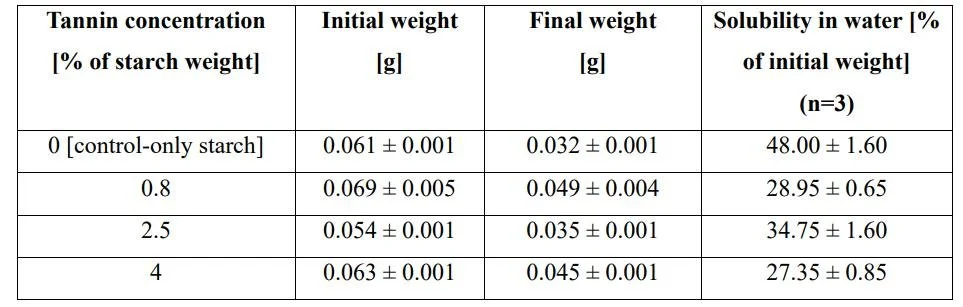

4.4. Solubility in water

The weight of the films before immersion was higher than that of the films after immersion and drying. However, the difference was not significant enough to disregard the film’s use as a packaging material. It is evident that the 0.8% tannin is optimal in terms of water solubility (Table 3), thus consolidating its position as the frontrunner for use as packaging material.

In comparison to previous research by Cano et al. [7], we can see that similar trends of declining water solubility with addition of tannins are observed in biofilms. Additionally, the results in the current research work are a definite improvement to those produced by Etxabide et al. [3], where the gelatine films are completely dissolved in water. This also proves the superiority of corn starch as a biopolymer.

4.5. Antioxidant properties

It is evident from the table below that as the concentration of tannins rises, the antioxidant activity also rises (Table 4). An optimal level of scavenging was again observed in the 0.8% tannin biofilm.

It is concluded that pure starch films do not express any form of antioxidant activity, and this is substantiated by current research, as observed in the above table. The optimality of the 0.8% tannin biofilm being optimal sits well with the findings by Etxabide et al. [3], which suggested optimal antioxidant activity at a 1% concentration of tannins.

Table 3: Solubility in water of biofilms

Table 4: Antioxidant activity of biofilms

Figure 7: Infrared spectra of the analysed biofilms

5. Conclusion

The aim of this research was to produce biofilms suitable for packaging foodstuffs. The films, using corn starch as a biopolymer, tannins as antioxidants, mechanical property enhancersand glycerol as a plasticiser, showed promising results.

The mechanical properties of the biofilms were evaluated in terms of Young's modulus, elongation at break, and tensile strength. They showed good improvement upon the addition of tannins to the starch films, and a concentration of tannins close to 1% was found to be optimal. Water contact angle was evaluated to test the hydrophobic character of the films, and again proved to be optimal in 0.8% tannin biofilms. Water solubility was also optimal in the 0.8 % tannin biofilms, and the films were of appreciable structural integrity.

The ABTS assay showed the presence of antioxidant activity in the tannin-infused biofilms and the colour changes were visible, confirming antioxidant character. The FTIR analysis confirmed polyphenolic presence, confirming the correctness of the ABTS assay.

6. Future work

This research supports the use of these films as packaging material. However, further analysis should be done to confirm and strengthen this evidence. Colour is one of the first attributes noticed in a material. The colour of films can be analysed using a colorimeter, and the data could be analysed using a CIELEB colour scale.

Furthermore, testing the solubility in food grade solvents will be an important step to ensure the stability of the packaging material and this can be initiated using ethanol. In addition, pH analysis is crucial in any research, and this will form a part of future analyses. There are few other analyses which could be performed as the research goes forward.

One thing is certain: these films have promise in transforming the packaging industry. When enhanced appropriately, this form of biodegradable packaging could be a ground-breaking innovation with significant benefits.

[1] N. Alqahtani, T. Alnemr, and S. Ali, “Development of low-cost biodegradable films from corn starch and date palm pits (Phoenix dactylifera),” Food Bioscience, vol. 42, p. 101199, Aug. 2021, doi: https://doi.org/10.1016/j.fbio.2021.101199.

[2] Jha and A. Kumar, “Biobased technologies for the efficient extraction of biopolymers from waste biomass,” Bioprocess and Biosystems Engineering, vol. 42, no. 12, pp. 1893–1901, Sep. 2019, doi: https://doi.org/10.1007/s00449-019-02199-2

[3] A. Etxabide, Y. Yang, J. I. Maté, K. de la Caba, and P. A. Kilmartin, “Developing active and intelligent films through the incorporation of grape skin and seed tannin extracts into gelatin,” Food Packaging and Shelf Life, vol. 33, p. 100896, Sep. 2022, doi: https://doi.org/10.1016/j.fpsl.2022.100896.

[4] W. Abotbina, S. M. Sapuan, M. T. H. Sultan, M. F. M. Alkbir, and R. A. Ilyas, “Development and Characterization of Cornstarch-Based Bioplastics Packaging Film Using a Combination of Different Plasticizers,” Polymers (20734360), vol. 13, no. 20, pp. 3487–3487, Oct. 2021, doi: https://doi.org/10.3390/polym13203487.

[5] B. Karthikeyan, R Prakash Raja, and D. Ramasamy, “Development and Characterization of Biodegradable Film Using Corn Starch,” Jun. 2016.

[6] [6] E. Basiak, A. Lenart, and F. Debeaufort, “How Glycerol and Water Contents Affect the Structural and Functional Properties of Starch-Based Edible Films,” Polymers, vol. 10, no. 4, p. 412, Apr. 2018, doi: https://doi.org/10.3390/polym10040412.

[7] A. Cano, M. Andres, A. Chiralt, and C. González-Martinez, “Use of tannins to enhance the functional properties of protein based films,” Food Hydrocolloids, vol. 100, p. 105443, Mar. 2020, doi: https://doi.org/10.1016/j.foodhyd.2019.105443.

[8] H. Ma, W. Qin, B. Guo, and P. Li, “Effect of plant tannin and glycerol on thermoplastic starch: Mechanical, structural, antimicrobial and biodegradable properties,” Carbohydrate Polymers, vol. 295, p. 119869, Nov. 2022, doi: https://doi.org/10.1016/j.carbpol.2022.119869.

[9] H. F. Chhatariya, S. Srinivasan, P. M. Choudhary, and S. S. Begum, “Corn starch biofilm reinforced with orange peel powder: Characterization of physicochemical and mechanical properties,” Materials Today: Proceedings, Feb. 2022, doi: https://doi.org/10.1016/j.matpr.2022.01.339.

Siddharth is a recently graduated Masters student in the field of food science. He graduated with first division honors and carried out this research under the guidance of Dr. Paul Kilmartin, where he attempts to produce biodegradable food packaging material to replace conventional plastic.